Some cool turbine blade manufacture photos:

Leading of the Globe Tower 90 – four

Image by Duke Power

Duke Power, Wanzek Building and Siemens staff assemble beneath Tower 90 at Duke Energy’s Top of the Globe Windpower Project near Casper, Wyoming. A single of the wind turbine blades atop Tower 90 was inspected by President Barack Obama on April 27, 2010 at the Siemens manufacturing facility in Ft. Madison, Iowa. The 44 Siemens wind turbines and 66 Basic Electric turbines at Prime of the World are capable of producing 200 megawatts of electricity – enough to power about 60,000 properties. PacifiCorp is buying all of the output from Prime of the Globe under a 20-year power buy agreement.

Image from page 363 of “Steam turbines a practical and theoretical treatise for engineers and students, like a discussion of the gas turbine” (1917)

Image by Internet Archive Book Photos

Identifier: steamturbinespra00moye

Title: Steam turbines a sensible and theoretical treatise for engineers and students, including a discussion of the gas turbine

Year: 1917 (1910s)

Authors: Moyer, James Ambrose, 1875-

Subjects: Steam-turbines

Publisher: New York, Wiley

Contributing Library: The Library of Congress

Digitizing Sponsor: The Library of Congress

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Pictures From Book

Click here to view book on the internet to see this illustration in context in a browseable on-line version of this book.

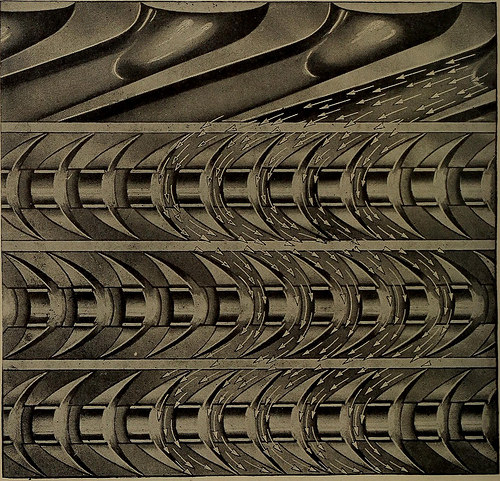

Text Appearing Ahead of Image:

Fig. i85g. Nozzle-plate for Curtis Ring Valve. It is comparatively a very effortless matter to get rid of some of thesteam which has been partly expanded in the turbine by theuse of appropriate automatic or hand-controlled valves even whenthe quantity of steam essential at a continual pressure in such ableeder line is quite variable. By this approach it is possible to 344 THE STEAM TURBINE extract the greatest amount normally achievable as required forgenerating power and at the same time supplying at a purpose-ably continual stress generally about atmospheric, or about5 pounds above, the requirements for heating or industrialpurposes. Fig. 185I1 shows the satisfactory filling of the blades of animpulse turbine of the bleeder kind.

Text Appearing Soon after Image:

Fig. 185I1. Flow Lines in a Bleeder Impulse Turbine. CHAPTER XI. BLEEDER OR EXTRACTION TURBINES. The name bleeder or extraction turbine is offered toone specially designed to take steam at boiler stress and toexhaust part of this steam at a generally low vacuum whileanother component is extracted or taken out from 1 of thestages at a stress of 5 to ten pounds per square inch gagepressure that is, just a tiny above atmospheric. In manycases, as for example in cotton, woolen, and paper mills, thissteam is extracted for manufacturing purposes, normally heat-ing water in vats. A lot more typically, however, such turbinesfind their application for supplying the low-stress steam re-quired in a heating method for homes, factories, workplace buildings,etc. Simply because this latter supply is needed only a portion of the yearand otherwise is variable with the seasons, there will be timeswhen the turbine operates by total expansion of all the steamsupplied to it by the boilers. Obviously it is required

Note About Photos

Please note that these images are extracted from scanned web page images that could have been digitally enhanced for readability – coloration and look of these illustrations may not perfectly resemble the original work.

Turbines and Towers

Image by brewbooks

Turbines and Towers

127 wind turbine generators, spanning across 9,000 acres near Ellensburg, Washington.

Towers are 221 ft higher at hub, 13.two ft wide base and 7.six ft wide at best and weigh 104 tons. Each turbine consists of 3-blades, 129 ft extended, 11.62 ft at widest and 1.6 ft at tip with every blade weighing 14,300 lbs. The rotor (blades, hub and nose cone) weighs 42 tons.

Turbine generators are V80-1.eight MW machines manufactured by Vestas, a Danish company. Each generator can make 690 volts, which is stepped-up to 34,500 volts by an on-board transformer. The generator is housed inside a fiberglass nacelle.

The generator and nacelle with each other weigh 69 tons.

Total height with a blade completely extended is 351 ft and total weight is roughly 270 tons. These are the biggest wind turbine generators in Washington State (as of 2007)

Each tower foundation reaches a minimum depth of 25 ft and a maximum of 32 ft based on bedrock depth and requires an typical of 100 to 260 cubic yards of concrete. Each foundation needs 120 anchor bolts that span from the surface of the ground to the bottom of the foundation. A single 28 ft anchor bolt weighs around 150 lbs.

Rotors turn 15.5 rpm, turning clockwise (front view) with a rotor diameter of 264 ft, larger than a wingspan of a Boeing 747.

Turbines can produce electrical energy at wind speeds as low as 9 mph, reaching their peak of production at 31 mph and shut down at continuous wind speeds of 56 mph. The prevailing winds are from the northwest.

Every single turbine is capable of generating 1.eight megawatts, or a total of 229 megawatts of capacity, enough electrical energy to serve about 73,000 properties when all 127 are creating at full capacity.

i042907 352