Verify out these compressor blade machining pictures:

Image from web page 65 of “Railway mechanical engineer” (1916)

Image by Net Archive Book Pictures

Identifier: railwaymechanica91newy

Title: Railway mechanical engineer

Year: 1916 (1910s)

Authors:

Subjects: Railroad engineering Engineering Railroads Railroad automobiles

Publisher: New York, N.Y. : Simmons-Boardman Pub. Co

Contributing Library: Carnegie Library of Pittsburgh

Digitizing Sponsor: Lyrasis Members and Sloan Foundation

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Pictures From Book

Click right here to view book on the web to see this illustration in context in a browseable on the web version of this book.

Text Appearing Ahead of Image:

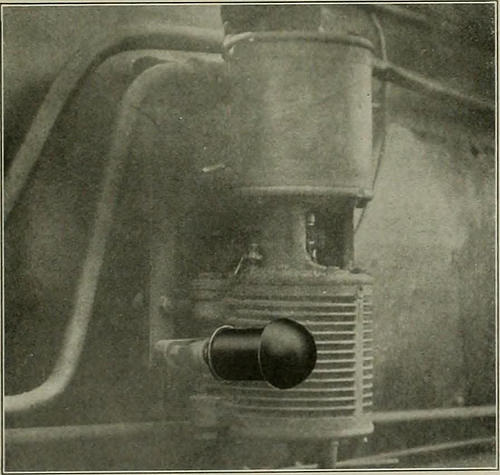

ill deal with 1 arc and is rated at 150amperes. The biggest machine, rated at 1,200 amperes, willhandle eight arcs at the exact same time. The arcs are operatedin multiple, hut a separate manage panel should be utilised foreach. The use of a separate control panel makes eachoperator completely independent of the other. A portablemachine for field use is mounted on a gasoline motor truckwhile the shop sort is mounted on a hand truck. AIR STRAINER FOR LOCOMOTIVE AIRPUMPS The Gustin-Bacon Manufacturing Company. Kansas City,Mo., has recently placed on the market place an air strainer forlocomotive air compressors which is created of malleable ironwith either Ij-in. or 2-in. fittings, and weighs 82 lbs. ^ tf °Taa^^ Section of the Locomotive Air Pump Strainer This strainer could be applied to the intake of the air com-pressor in either the horizontal or vertical position. It con-sists of a six-in. by four-in. cylinder, filled with oil-soakedcurled hair, by means of which the air should pass just before it reaches

Text Appearing Following Image:

strainer Applied to the Air Pump the cylinder. This cleans the air of foreign matter just before itpasses to the compressor. The strainer is offered with ahood that overlaps the outer wall of the cylinder for a single inch. so that the air is drawn in from the below side of the hoodand not directly into the strainer. This construction pre-vents rain or snow from acquiring into the strainer and finallyworking into the cylinder. It also prevents the possibilityof squirting oil into the compressor, a practice that is be-coming too widespread with the enginemen. The curled hairbeing soaked with oil will stop the strainer from freezingin cold climate. HACK SAW MACHINE A new hack saw machine has Ijeen placed on the marketby the L. S. Starrett Business, Athol, >Iass., which includesa quantity of intriguing features. It is the initial machine tobe put on the industry b- this compan)-, and was developedbecause of its connection in the metal cutting industrieswhere its hack saw blades are utilized. There are fou

Note About Photos

Please note that these photos are extracted from scanned web page pictures that might have been digitally enhanced for readability – coloration and look of these illustrations may possibly not perfectly resemble the original perform.

Image from page 377 of “Railway mechanical engineer” (1916)

Image by Net Archive Book Pictures

Identifier: railwaymechanica89newy

Title: Railway mechanical engineer

Year: 1916 (1910s)

Authors:

Subjects: Railroad engineering Engineering Railroads Railroad automobiles

Publisher: New York, N.Y. : Simmons-Boardman Pub. Co

Contributing Library: Carnegie Library of Pittsburgh

Digitizing Sponsor: Lyrasis Members and Sloan Foundation

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Pictures From Book

Click here to view book online to see this illustration in context in a browseable on-line version of this book.

Text Appearing Before Image:

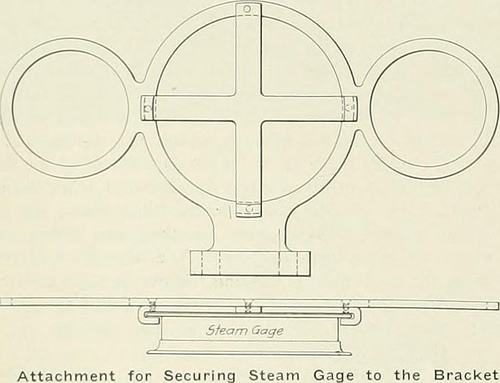

ork. Yet another noticeablefeature of the new arrangement is the utilization of reduce pricedtool steel for tool manufacture. For instance, by insertinghigh speed blades in rose reamers, a reamer two in. in diameterby 16 in. lengthy becoming regarded as, the cost of the raw materialif produced strong is .86 cost for inserted blades as fol-low-s: Six pieces high speed steel V/i in. by Yz by three]4 in- weigh-ing much less than one particular pound and 14 lb. of soft steel worth IScents per pound or a material expense of roughly 71cents. The progress so far made only serves to emphasize the goodthat can be accomplished by means of enterprise management in rail-way shops. THE Cost OF COMPRESSED AIR Technique OF SECURING STEAM GAGES BY W. S. WHITFORDChicago & North Western, Milw The illustration shows a steam gage bracket to which has beenapplied a simple attachment for holding the gage in positionwithout the use of bolts or machine screws. The device, origi-nated by J. Linnehan. a machinist at this point, is simply created

Text Appearing Soon after Image:

to the Bracket from strips of three/16 in. boiler steel, the ends of which at the bot-tom and sides of the bracket arc bent so that they hold the rimof the steam gage securely in spot when the pipe union is con-nected. By disconnecting the union the gage may possibly be removed. BY THOMAS F. CRAWFORD Twenty years ago when pneumatic tools have been in their infancythe installation of an air compressor did not demand the care-ful study which is now essential, since the great savingin time effected by tlie substitution of air tools for hand toolsovershadowed all other costs. Right now, even so, as an alternative of aluxury to be located in only the greatest and most progressive shopscompressed air is used in each conceivable plant from the two-stall roundhouse on some isolated branch line to the 40-pit mainshop at division headciuarlers. . cautious study uf tl.e development of the compressed air systemin the typical shop reveals tlie truth that the original technique hasbeen steadily extended by additions, owing to the a lot of a

Note About Images

Please note that these images are extracted from scanned web page images that could have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original operate.

Image from page 444 of “Railway and locomotive engineering : a practical journal of railway motive power and rolling stock” (1901)

Image by World wide web Archive Book Photos

Identifier: railwaylocomotiv17newy

Title: Railway and locomotive engineering : a sensible journal of railway motive power and rolling stock

Year: 1901 (1900s)

Authors:

Subjects: Railroads Locomotives

Publisher: New York : A. Sinclair Co

Contributing Library: Carnegie Library of Pittsburgh

Digitizing Sponsor: Lyrasis Members and Sloan Foundation

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Pictures From Book

Click here to view book online to see this illustration in context in a browseable on-line version of this book.

Text Appearing Prior to Image:

^ oz. Drop Forged Steel. Alwaysuseful. Ever Ready. In Leather Case. Value, .50 WILLIAMS, FROST & CO. WINONA, MINN. September, 1904. RAILWAY AND LOCOMOTIVE ENGINEERING 43 THIS

Text Appearing Following Image:

BOOK on pumping, air-compressing antlcondensing machinery is Provided Away by each of the following businesses : Henry R. WorlhingtonLaidlaw-Dunn-Gordon-Co.Blake-Knowles Steam Pump WorksDeane Steam Pump WorksClayton Air Compressor Functions 114-118 Liberty Street, New York Versatile Spout The Higley Cold Metal Saw. The principal tiling which strikes anobserver as he appears at a Higlcy coldsaw at operate is the way it is driven.You have seen a man take hold of thespokes of a cart wheel when his vehicleis nicely nigh stuck quick, and support thetugging group. He catches the spokesnear the rim and pushes on them withmight and main nicely, that is prettymuch the way a ?Iigley saw is driven.Motion is offered to the saw blade by a.^lieer steel sprocket wheel meshing inradial slots placed as near the periph-ery as achievable. The slots, however,leave sufficient depth beyond to permitof the frequent regrinding of the saw. On machine size No. 21, which youcan see in the P. & R. shops at Study-ing and in other railr

Note About Images

Please note that these pictures are extracted from scanned web page photos that may have been digitally enhanced for readability – coloration and look of these illustrations may possibly not completely resemble the original operate.