A handful of nice pump impeller machining images I located:

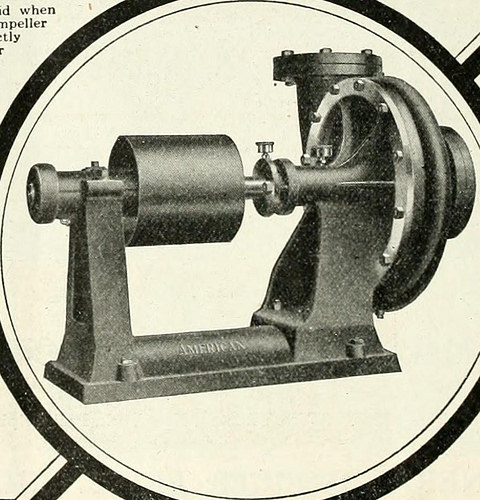

Image from page 382 of “Engineering and Contracting” (1909)

Image by Internet Archive Book Pictures

Identifier: engineeringcontr29chicuoft

Title: Engineering and Contracting

Year: 1909 (1900s)

Authors:

Subjects:

Publisher: Chicago

Contributing Library: Gerstein – University of Toronto

Digitizing Sponsor: MSN

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Photos From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

g accurately machined to t^auvre on both sides and diameter and perfectlyadjusted in the volute, it is not possible for the water to pass the impellerand churn in the casing in the AmericanCentrifugal Pump and the complete mechanical action contributes straight to the higher-est attainable efficiency, saving totally. 2h^tc of the expense ofoperation. The unique design and style of the impeller enables the single stagepump to operate economically against higher heads, saving theadditional initial cost and increased expense of operation of multi-ple stage pumps. American Pumps are sold beneath a guaranty that they willgive a mechanical efficiency of 60 to 807o. according to size, andthat they will not use far more energy than is specified in our table ofhorse power required. Theres a revelation in pump efficiency toengineers and contractors in our catalog and we mail it totally free on request. The American Nicely Performs, centrifugal pumps* General Office and Functions. Aurora,Chicago Office: Very first Natl Bank BIdg. llinois, U. S. A.

Text Appearing Soon after Image:

IN WRITING to our Advertisers for CATALOGS or Rates please mention ENGINEERING-CONTRACTING. May 20. IQ08. ENGINEERING-CONTRACTING six/

Note About Images

Please note that these photos are extracted from scanned page photos that may possibly have been digitally enhanced for readability – coloration and appearance of these illustrations may possibly not perfectly resemble the original function.

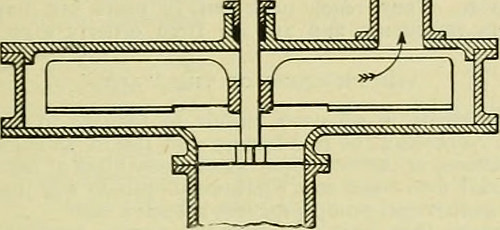

Image from web page 452 of “American engineer and railroad journal” (1893)

Image by Internet Archive Book Photos

Identifier: americanengineer68newy

Title: American engineer and railroad journal

Year: 1893 (1890s)

Authors:

Subjects: Railroad engineering Engineering Railroads Railroad automobiles

Publisher: New York : M.N. Forney

Contributing Library: Carnegie Library of Pittsburgh

Digitizing Sponsor: Lyrasis Members and Sloan Foundation

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Images From Book

Click right here to view book on the internet to see this illustration in context in a browseable on the web version of this book.

Text Appearing Just before Image:

will ilo. This extraordinary reportstands printed in a Government publication, signed by menwho had been, or are, eminent in mechanics, and we can only de-plore the stupidity as properly as presumption of the commis-sion who therefore disposed of a subject that had twenty years be-fore been cautiously investigated by such males as Sir John Reu-nie, Professor Cowper, Mr. Whitelaw, Dr. James Black, Pro-fessor Rankine, and many other individuals. The most astonishing partis, nevertheless, that this report was passed and signed by menwho we can hardly suppose would fail to perceive its absurdity. BLAKES PUMP. Returning once again to American pumps, in 1831 Messrs. Blake,of the New Steam Mills, in Connecticut, invented 1, shownin fig. 15, and effectively worthy of focus here as being the firstof its variety, and virtually identical with Bessemers of 1843 and1849. It is, in truth, the greater machine if carefully compared,but subject, like nearly all disk pumps, to lateral thrust uponthe impeller that would cause difficulty in functioning.

Text Appearing Following Image:

Fig- IS- It was in every sense a departure, and is by no meansobsolete at this day for high lifts. The force of the issuingwater, or its tangential energy, is lost, as may be noticed by theannular casing and modify of the waters course, but this losshas to be measured by the relative speed among the wheel andoff-flowing water, as has been explained. This invention hasof correct a prominent place in the history of centrifugal pumps. Andrews pcmp. The subsequent American pump to follow was that of Andrews,invented or published in 1839, the initial American pump with acylindrical discharge chamber. If the Massachusetts pumpcame close to anticipating our very best modern day practice, the Andrewspump completed the matter, and leaves room for the lamentof Lord Byron that those thieving ancients have stolen all ofour modern concepts. The building, in side view, is identical with the Massa-chusetts pump invented in 1818, and shown in fig. 13, thedifference not demanding a new drawing, Andrews inven-tion relating t

Note About Pictures

Please note that these images are extracted from scanned page images that might have been digitally enhanced for readability – coloration and appearance of these illustrations might not perfectly resemble the original operate.

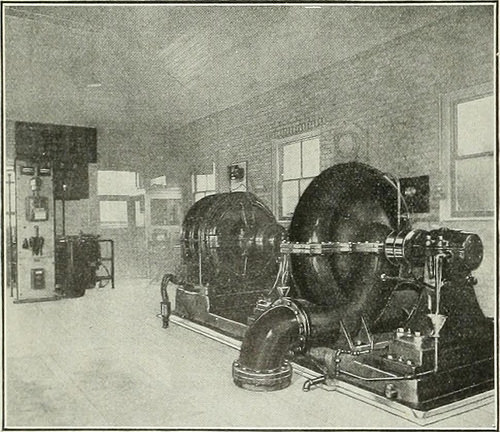

Image from web page 30 of “Electrical news and engineering” (1891)

Image by Web Archive Book Photos

Identifier: electricalnewsen27donm

Title: Electrical news and engineering

Year: 1891 (1890s)

Authors:

Subjects: Electrical engineering

Publisher: Don Mills, Ont. [and so on.] Southam-Maclean Publications

Contributing Library: Engineering – University of Toronto

Digitizing Sponsor: University of Toronto

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Images: All Pictures From Book

Click here to view book online to see this illustration in context in a browseable on the internet version of this book.

Text Appearing Ahead of Image:

is far higher than any corresponding percentage sav-ing in the energy consumption of the exact same machine. The author sums up the relative benefits in Taljle TI. Pumping Plants Have Gear Designedfor Flexibility The motor-driven centrifugal pumping plant recentlycompleted at the Riverdale station of the corporation of To-ronto is of interest to municipal and other engineers, owingto the wonderful flexibility of speed and capacity of the unit. Itwas made to provide .j.000,000 imperial gallons in 24 hours,against a head of 170 feet, and operating at a speed of 720 r.p.m.,but owing to probable variation in pressure and capacity thecity needed the unit to deliver either >,00U.000 gallons or1,000,000 gallons against a decrease head varying from lliO ft.down to 70 ft. Single Stage Pump With Variable Speed Motor Under such conditions it is usual to build a multi-stagepump, but the contractors. Canadian AUis-Chalmers, designedand built a single-stage pump which has fulfilled all the guar-

Text Appearing Following Image:

Unil at Riverdale pumping station, Toronto. antees necessary by the city. The fjsual practice also is tosupply constant speed induction motors for centrifugalpumps, but as the speed to fill the above needs mustvary from 720 r.p.m. down to 50 r.p.m., the Canadian GeneralElectric Organization built a specific 250 h.p. variable speedmotor, which also fulfils all the needs of the city. This pump is single-stage, split casing, specially designedand constructed to obtain the highest efficiency. It consistsof a cast-iron spiral casing with discharge and suction inletcast on to the reduced physique. The casing is split on a horizon- tal centre line, so as to facilitate inspection with no dis-mantling pipe or any other part of the unit. A set of removable diffusion guide vanes has been pro-vided so as to guide the water from the impeller to the cas-ing in the most efficient manner. The impeller is made ofcast bronze, and is polished so as to get rid of unnecessaryfriction. Particular neck rings h

Note About Photos

Please note that these images are extracted from scanned web page pictures that could have been digitally enhanced for readability – coloration and look of these illustrations may possibly not perfectly resemble the original work.