Check out these turbine blade machining images:

CV-990 Number 4 (outer correct) engine

Image by wbaiv

This is the CJ-805, the 1 and only aft-fan turbofan ever put in service. The totally free turbine is aft of all of what is generally a J-79 and has the fan blades around its outside diameter. The massive ducts about the core enable the fan to suck air through the principal intake. Mechanically its quite neat, aerodynamically probably not so neat.

103-0342_IMG

Image from web page 390 of “Twentieth century hand-book for steam engineers and electricians, with inquiries and answers ..” (1905)

Image by Net Archive Book Photos

Identifier: twentiethcentury03swin

Title: Twentieth century hand-book for steam engineers and electricians, with concerns and answers ..

Year: 1905 (1900s)

Authors: Swingle, C. F. [from old catalog] Horstmann, Henry Charles, 1858- [from old catalog] Tousley, Victor Hugo, 1875- [from old catalog]

Subjects: Steam engineering Electrical engineering Steam turbines

Publisher: Chicago, F. J. Drake & co.

Contributing Library: The Library of Congress

Digitizing Sponsor: The Library of Congress

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Images: All Pictures From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Ahead of Image:

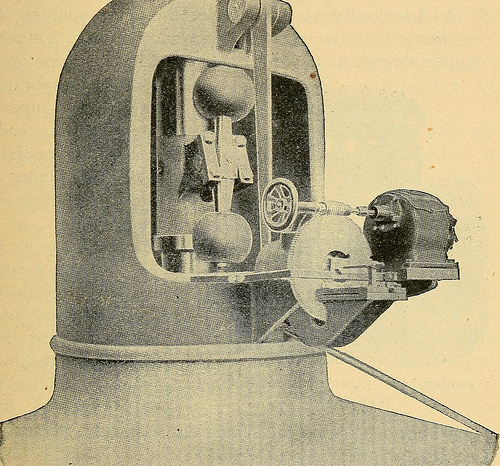

olled by piston valves, which are actuated bysteam from small pilot valves which are in turn underthe handle of the governor. Fig. 139 shows the formof governor for a 5,000 K. W. turbine, and Fig. 140shows the electrically operated admission valves forone set of nozzles. Speed regulation is effected by varying the numberof nozzles in flow, that is, for light loads fewer nozzlesare open and a smaller sized volume of steam is admitted tothe turbine wheel, but the steam that is admittedimpinges the moving blades with the same velocityalways, no matter whether or not the volume be massive orsmall. With a complete load and all the nozzle sections inflow, the steam passes to the wheel in a broad belt andsteady flow. The Curtis Steam Turbine is the result of the investi-gations and experiments of Mr. C. G. Curtis of New THE CURTIS STEAM TURBINE 370 York, and while retaining the benefit of the expand-ing nozzle of De Laral, it at the very same time utilizes theenergy acquired by velocity, by causing the steam to

Text Appearing Soon after Image:

FIGURE 139. GOVERNOR FOR 5,000 K.W. TURBINE. impinge the moving buckets of two or more wheels insuccession. A portion of this velocity force is givenup in the 1st stage, and yet another portion in the secondstage, and this method is repeated, the steam in each and every 380 ENGINEERING case getting 1st caused to expand in divergent nozzlesand as a result acquire new velocity just before it is allowed toimpinge the moving blades of the subsequent reduce stage. Thepressure in each and every succeeding stage of expansion becomeslower and reduced, till finally vacuum is reached. As previously stated, two of the main sources ofeconomy that the steam turbine possesses in a muchhigher degree than does the reciprocating engine are: very first, its adaptabilityfor using super-heated steam, andsecond, the possibil-ity of maintaining ahigher degree ofvacuum. k The efficiency I I shown by the steam HH 1 turbine is certainly ^mx^- – ■ outstanding, and one particular .jr peculiar feature re- ^**—_—_——*_- garding the machine is, that its effi

Note About Pictures

Please note that these pictures are extracted from scanned page images that may possibly have been digitally enhanced for readability – coloration and appearance of these illustrations may possibly not perfectly resemble the original work.