Verify out these turbine blade producers photos:

Image from web page 302 of “Electrical news and engineering” (1891)

Image by Web Archive Book Pictures

Identifier: electricalnewsen28donm

Title: Electrical news and engineering

Year: 1891 (1890s)

Authors:

Subjects: Electrical engineering

Publisher: Don Mills, Ont. [etc.] Southam-Maclean Publications

Contributing Library: Engineering – University of Toronto

Digitizing Sponsor: University of Toronto

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Pictures From Book

Click right here to view book on the internet to see this illustration in context in a browseable on the web version of this book.

Text Appearing Before Image:

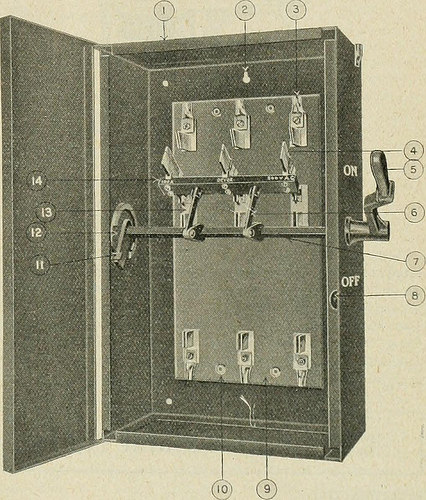

packed in person carton withlaiger model, o. 1), is in1 im he !,, prime ol motoi. u itli bladi diann lei olVttracth ■ i indo displa material ctive l.d.cl. Anothertop i guard and I! ■ mi InsIn n i l tl, consi till a mihiw stii kers, .ton i ird folders, raphi d i utoul and so on. I be i ompanj late th il thi nd final yeai fm Iolai ub in the Devoe Electric Switch Firm, Montreal. Sev-eral features in connection with this switch are outlined bytin manufacturers. The moving arms are constructed insuch a way as to give constructive motion to the blades whichall enter their contacts at the very same time. With this con-struction there is no danger of a 3 phase motor runningsingle phase or beginning fuses becoming blown a slotted screwbole is supplied enabling a single man to set up the box the

Text Appearing Right after Image:

base is of Monson slate locking device to avoid switchfrom being closed blades of 98$ pure copper created tomake .mi, get in touch with snap catch with bole for padlock extraheavy cast iron deal with robust verify preventing strain onswatch when operating. All Devoe security switches an e:amined and labelled beneath path of the HydroelectricPower Commission of Ontario. In connection with the reconstruction of the plant oithe Saguenaj Light & Energy Co., Ha! Ha! Bay, P.Q., the order for the turbine has been awarded to the S. MorganSmith Co., York. Pa. The unit is 800 h.p., the wheel beingof the single horizontal sort, one hundred r.p.m., functioning undei a .- i head. It is to he direct connected to the generator, and will replace an obsolete turbine. This energy, in No. 2 p w e rcurrent wphite Co.1, ngtfi hi nisiill b and ol stl will be in parallel with No. I power, and theuse at the mill of Hal Hal Baj Snlu li.n i terminals. The order involves api nstoi I. to, it thplait by the out l lb. Bellto t

Note About Images

Please note that these images are extracted from scanned web page pictures that could have been digitally enhanced for readability – coloration and look of these illustrations could not completely resemble the original function.

Image from web page 597 of “Electric railway evaluation” (1906)

Image by Web Archive Book Pictures

Identifier: electricrailwayr18amer

Title: Electric railway assessment

Year: 1906 (1900s)

Authors: American Street and Interurban Railway Association

Subjects: Street-railroads Electric railroads

Publisher: Chicago : Wilson Co

Contributing Library: Carnegie Library of Pittsburgh

Digitizing Sponsor: Lyrasis Members and Sloan Foundation

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Photos From Book

Click right here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Just before Image:

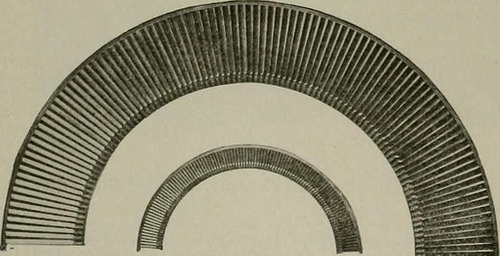

o be sensible mechanically up to the limitsset by the generators to which the turbines are connected.Appreciating this, some producers are voluntarily incur-ring the expense of building new requirements. Issues Overcome. Each and every variety of turbine had its inherent difficulties to beovercome ahead of the specifications of commercial operationcould be met satisfactorily. In the reaction, or Parsons-sort,an critical supply of loss in efficiency is the steam leakingpast the ends of the blades without carrying out work. It is desir-capable, therefore, to lessen this loss to a minimum. The quan-tity of steam hence lost past a ring of blades depends uponthe peripheral length of the ring, the percentage that theclearance is of the length of the blades in the ring, and theclearance at the ends of the blades. Certainly, then, leak-age will be greatest more than the shortest blades. The impact ofspeed upon economy, here, is self-evident. Improve of speedand consequent lower In rotor- and cylinder-diameterB

Text Appearing Soon after Image:

Note About Pictures

Please note that these photos are extracted from scanned web page images that may possibly have been digitally enhanced for readability – coloration and appearance of these illustrations might not perfectly resemble the original operate.

Miss Madison

Image by W9NED

Miss Madison

Hull Specifications

Division:

Unlimited Hydroplane (U-6)

Designer-Builder:

Dale Van Weiringen, Rick Bowles, Mike Hanson, Larry Hanson, Madison crew

Length: 30 ft.

Width: 14′ 5"

Weight: 6775 pounds

Gearbox: 50% reduction

Fuel: 60 gallons / Jet A

Propeller:

13-eight-MO Stainless / three Blade – 26" Pitch – 16" Diameter (pitch will differ)

Building Material:

Composite supplies (Honeycomb aluminum, Fiberglass, carbon fiber )

Engine:

The Lycoming T-55 L-7 engine is a shaft turbine, rated at 2,650 horsepower at the output shaft. This engine was utilised in the Vietnam era by the twin engine Chinook Helicopter.

Manufacturer: Avco Lycoming Output Shaft: 15,300 RPM Compressor Ratio: 7:1

Weight: 600 pounds Oil Capacity: 5 gallons

Cockpit style:

The Madison Racing hydroplane utilizes a canopy from an F-16 jet fighter to safeguard the driver. The canopy is attached to a roll cage, which is bolted to a typical core cockpit. The driver sits in a form fitted seat using a 5-point harness to hold him in the seat. He also is supplied with compressed air and oxygen mask to facilitate breathing must the cockpit fill with water.

Miss Madison Racing Hulls

(1961 – present)

U-six Miss Madison (1st)

1961 – 1963

(Former U-79 Nitrogen)

U-6 Miss Madison (2nd) **

1963 – 1971

(Former U-79-two Nitrogen Too)

U-six Miss Madison (3rd)

1972 – 1977

U-six Miss Madison (4th) ***

1978 – 1988

(Former U-25 & U-1 Pay ‘n Pak

& U-76 Atlas Van Lines)

U-six Miss Madison (5th)

1988

U-6 Miss Madison (6th) *

1988

U-six Miss Madison/Oh Boy! Oberto

(7th)

2007

* When the new Miss Madison crashed at San Diego in 1988, the Miss Madison group leased the U-three Risley’s hull from owners Ed Cooper, Sr., and Ed Cooper, Jr., for the final race of the year in Las Vegas. The U-three was officially the U-six Miss Madison at this 1 occasion.

Miss Madison Power Plants

Allison V-12: 1961 – 1990

Lycoming Turbine: 1991 – present