A few nice impeller manufacturing pictures I discovered:

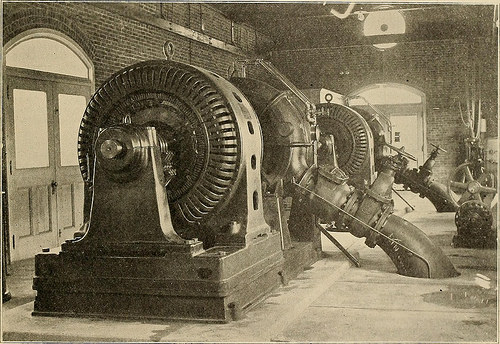

Image from web page 162 of “Journal of electrical energy, power, and gas” (1899)

Image by Net Archive Book Images

Identifier: journalofele241251910paci

Title: Journal of electricity, power, and gas

Year: 1899 (1890s)

Authors: Pacific Coast Electric Transmission Association

Subjects: Electrical engineering Electrical energy Gas manufacture and works

Publisher: San Francisco : Technical Pub. Co.

Contributing Library: San Francisco Public Library

Digitizing Sponsor: California State Library Califa/LSTA Grant

View Book Web page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Photos From Book

Click right here to view book on-line to see this illustration in context in a browseable on the web version of this book.

Text Appearing Prior to Image:

on-nected to a single suction, enclosed impeller centrifugal pumpmade by the Holly Manufacturing Firm, Buffalo. Energy generated at Niagara Falls is transmitted to North within the specifications, and that the pump capacities andhorsepowers are well exceeded. Itesiilt ol TcNtw oi l.ui>kpurt*N Motor Driven Puiiiiiiiip: IiiKn. Pump 1. Pump two. Pump :). Maximum ie-. per miii,… 746 752 711 Minimum 738 738 739 Typical 743 744 743 Maximum gauge pres. lbs. 142.5 144.five 143.5 Minimum . 119.five 139.five 134.five Typical ■ . 136.9 142.6 138.9 Typical liead, £eet 316.eight 329.1 320.six Gallons pumped per hour. . 238,000 236,300 236,700Gallons pumped in 24 hrs. at this rate five,712,000 five,672,000 five,712,000 Kilowatt input per hour.. 342.four 346.1 341.five Gallons per kilowatt hour 1,454 1,464 1,443 Hydraulic horsepower…. 318 327 319,five Electric horsepower 456.six 456 455 Efficiency per cent 69.six 71 70 Duty. foot-pound per 1000 k. w 30.800,000 31,600.000 31,000.000 Liegrees temperature rise in 15 hours 41 38 43

Text Appearing Right after Image:

EIr Dri rn PiiiniJ ul Luikport . V. Tonawanda at 22,000 volts and is stepped down to 440 voltsat the pumping station by three 500 kilowatt, oil insulated,water cooled transformers. The 3 motor driven pumping units have been recentlygiven a really complete test, which created some interestingeconomics of electric operation. Each unit was run contin-uously for 15 hours, in the course of which time readings of the elec-trical input were taken each five minutes readings of theVenturi water meter each ten minutes stress gauge everyfive minutes, and revolutions of pump every fifteen minutes.The benefits are provided in the accompanying table, which showsthat all three of the pumps exceeded the duly re(|Uiremeiil i>!27,000,000 foot-pounds by approximately four.000,000 foot pounds.It will be further noted that the temperature rises are nicely In the case of the Lockport pumping station, electricalenergy is purchased at .00 per horsepower year. The costof energy for this station is as a result just about equ

Note About Images

Please note that these photos are extracted from scanned web page photos that may have been digitally enhanced for readability – coloration and look of these illustrations may not completely resemble the original operate.

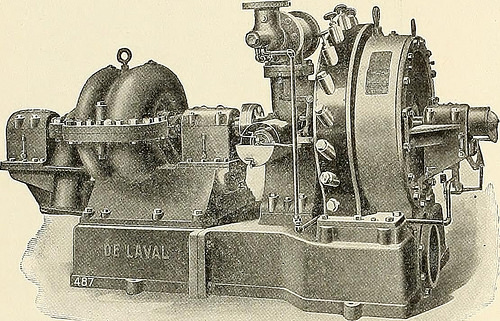

Image from page 233 of “Journal of electricity, power, and gas” (1899)

Image by Web Archive Book Photos

Identifier: journalofele241251910paci

Title: Journal of electrical energy, energy, and gas

Year: 1899 (1890s)

Authors: Pacific Coast Electric Transmission Association

Subjects: Electrical engineering Electricity Gas manufacture and performs

Publisher: San Francisco : Technical Pub. Co.

Contributing Library: San Francisco Public Library

Digitizing Sponsor: California State Library Califa/LSTA Grant

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Images From Book

Click right here to view book on-line to see this illustration in context in a browseable online version of this book.

Text Appearing Ahead of Image:

ce wtiile receiving tiny, and oftenunskilled, focus. For this reason the simple direct-actingpump has long held the field, in spite of its numerous short-comings such as an huge steam consumption, tendencyto generate shock and vibration, unsuitability for close regula-tion, numerous valves, and so on. The centrifugal boiler feeder, which has lately beentaken up by many of the biggest steam power plants in theUnited States, is cost-free of these defects and possesses severalimportant advantages in addition. It does not endanger thepipe line by vibration, by excessive pressure, nor by shock.The inflow of water can be regulated at the boiler with no ref-erence to the pump. A centrifugal boiler feed pump con-tains no valves and only two packings, of fairly small diam-eter, to be kept tight against hot water. There is no dangerof breakage of pistons, cylinder heads or iiacking ringsthrough loss of suction and consequent pounding. The ad-herents of the direct acting pump have asserted that with

Text Appearing Right after Image:

Turbine Driven Centrifutjal Boiler Feed Pump. the i)ump in motion the operator can usually be certain thatwater is going into the boiler, but this supposed advantagedoes not get where 1 or much more pumps are feeding severalboilers and, additionally, it is really attainable for a piston pumpwith one particular valve displaced to run steadily without forcingwater into the boiler. A single point that has retarded the introduction of thecentrifugal boiler feed pump is the fact that it is not suitedto reciprocating engine drive, as the comparatively low speedof the latter makes needed a huge number of stages inorder to obtain the high heads essential to overcome modernboiler stress and if an try is made to keep down thenumber of stages by making the impeller big in diameter,the efficiency is seriously reduced. Nevertheless, if the luimpis to be driven by a steam turbine or electric motor this be-comes an benefit. For instance, the impellers of the two-stage steam turbine driven pump shown by the accompanyin

Note About Pictures

Please note that these pictures are extracted from scanned web page pictures that might have been digitally enhanced for readability – coloration and appearance of these illustrations may not completely resemble the original operate.