Some cool turbine blade machining photos:

Image from page 291 of “Electrical news and engineering” (1891)

Image by Internet Archive Book Images

Identifier: electricalnewsen27donm

Title: Electrical news and engineering

Year: 1891 (1890s)

Authors:

Subjects: Electrical engineering

Publisher: Don Mills, Ont. [etc.] Southam-Maclean Publications

Contributing Library: Engineering – University of Toronto

Digitizing Sponsor: University of Toronto

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Photos From Book

Click right here to view book on-line to see this illustration in context in a browseable on-line version of this book.

Text Appearing Just before Image:

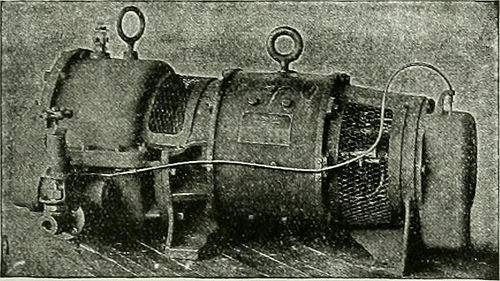

and the solution is uniform in flexibility. Each and every foot is fishedby an automatic fishing device invented by themselves. Thecompany additional state that Kraft Cord Braiduct is regu-larly inspected and labelled by the Underwriters Laboratory,below the path of the National Board of Fire Under-writers, and every coil carries the Underwriters label. Westinghouse Brings Out Small Turbo-Generator Unit.The Westinghouse Electric & Manufacturing Companyhas not too long ago made a little turbo-generator unit for di-rect-present service. This unit is created for 10 kilowattsoutput, despite the fact that a temporary load of roughly 12..5kv. might be obtained. The most important feature of thisunit is that it is but one revolving element in which the gen-erator shaft is extended so that it also carries the turbinerotor. This nut only makes a quite compact machine, but

Text Appearing After Image:

eliminates all coupling and misalignment troubles, and dis-penses with turbine bearings and packings. The turbinerotor is made of a high grade open hearth steel forging ac-urately completed, in the periphery of which are placed bladesof electric furnace steel which are held in spot by pinstightly driven in by way of blade and rotor. The blades are ofthe impulse variety and even though there is only one row ofblades yet by indicates of a reversing chamber the exact same steamis passed via the blades a second time, hence allowing total expansion of the steam. Since the unit is design-ed to occupy the least attainable space, the manufacturer hasequipped the generator with ball bearings (no bearings be-ing necessary on the turbine rather of the usual variety of sur-face bearing thus saving in bearing friction with a conse-quent lower in length and weight of the unit is efl^ected.Additionally these self-aligning ball bearings on tiny unitsare suited for a variety of services, especially for marinework w

Note About Pictures

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations might not perfectly resemble the original function.

Image from web page 1288 of “Electric railway evaluation” (1906)

Image by Internet Archive Book Images

Identifier: electricrailwayr19amer

Title: Electric railway overview

Year: 1906 (1900s)

Authors: American Street and Interurban Railway Association

Subjects: Street-railroads Electric railroads

Publisher: Chicago : Wilson Co

Contributing Library: Carnegie Library of Pittsburgh

Digitizing Sponsor: Lyrasis Members and Sloan Foundation

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Photos From Book

Click here to view book online to see this illustration in context in a browseable on-line version of this book.

Text Appearing Before Image:

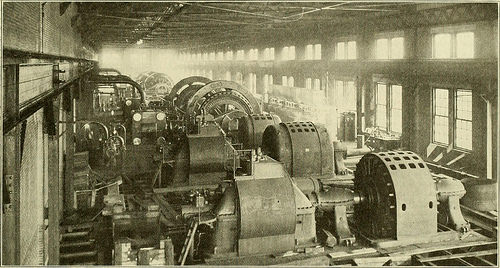

ibrium. In modest machines, nonetheless, the advan-tages of the double-flow principle are not as pre-eminent as inthe large, principally due to the fact of the absence of the necessitytherefor from a mechanical standpoint, and by purpose of thefact that the economy of two little machines is not most likely to Might 30, 190S. ELECTRIC RAILWAY Review 643 be as excellent as a single of twice the capacity. In turbines of verylarge size, nevertheless, exactly where proportions exist far more favorableto the attainment of higher economy, the latter advantage doesnot acquire. The double-flow turbine might hence be regarded as theresult of an insistent demand for turbine-creating units of illustration that considering that the two components are identical, and thesteam flows through them in opposite directions, the axialthrust of the steam on the blades, due to the difference ofpressure in between the inlet and outlet of each element, will beexactly the same in both sections. For that reason, perfect steambalance below all situations of stress, vacuum and load, is

Text Appearing Right after Image:

Westinghouse Double-Flow Turbines—Interior of Brunot Island Station of the Pittsburg Railways Organization, Showing Turbines During Erection. bigger capacity at high speeds. For the big machines, theadvantages of the combined impulse and reaction principle ofsteam expansion, with each other with the double-flow construction,are so critical that the sensible outcome, as embodied in themachine under description, is most fortunate. The Parsonsand the double-flow sort are virtually upon the very same basis obtained with no the use of dummy or balance pistons. Asthese low-pressure turbines are designed to utilize all theexhaust steam from a non-condensing reciprocating engine, itis attainable to tie the engine and turbine with each other electrically,hence producing the use of a governor on the low-stress turbineunnecessary. With the exception that, as pointed out, the gov-

Note About Images

Please note that these photos are extracted from scanned web page pictures that may possibly have been digitally enhanced for readability – coloration and look of these illustrations may not completely resemble the original perform.